High Performance Clothing And Food Needle Metal Detector With Conveyor Belt

High Performance Clothing And Food Needle Metal Detector With Conveyor Belt

Application :

Clothings and foods needle metal detector with conveyor belt is used mainly for food and other requirements of high detection sensitivity industries, for the detection of inclusions or lost in the raw materials or products of Broken Needle, wire or lead, copper, aluminum, tin, stainless steel and other metals.

working principle

Upper and lower head of the magnetic coil by the access needle and

the machine's power to work together to form a magnetic needle,

when iron and other substances with different properties of iron

into the needle area, it will cause a change in the local magnetic

field, and thus fluctuations in the magnetic field caused by local

instantaneous current. Perceived abnormal current will be

transferred to the control board, and set a good sensitivity

compared with the needle before; when the current value of this

change reaches or exceeds value flu needle devices in use when the

set time, machine control board will make the alarm, stop, rewind

the belt so that a series of instructions; and finally complete it

some action.

Feature:

1. The latest development of highly integrated chip, ensure high

performance and high reliability;

2. High sensitivity, high anti-jamming capability;

3. The data collected from all motor control using digital signal

processing (DSP), highly intelligent;

4. Easy to use, automatic data processing and preservation, setting

off every time to keep the boot;

5. The self-developed high-frequency switching power supply, fit

and strong;

6. The use of integrated design, optimization of product design,

reduce component count by computer instead of sophisticated

electronic components, so the failure rate times reduced;

7. The precise control of the timing of the motor by the computer,

to extend the life of the motor;

8. accurate count, qualified, defective, the total number;

9. unmanned operation is automatically shut down;

Spectifications:

Model | W801 | |||||

Window Height | 100mm | 120mm | 150mm | 200mm | 250mm | |

Window Width | 440mm | 440mm | 440mm | 440mm | 440mm | |

Sensitivity | Fe Diameter>= | 0.6mm | 0.8mm | 1.0mm | 1.2mm | 1.5mm |

SUS Diameter>= | 1.5mm | 1.8mm | 2.0mm | 2.5mm | 3.0mm | |

Power | 220V,50HZ,120W | |||||

Composition structure

1, the detection sensor (probe)

2, the circuit control system

3, the electrical machine

4. The conveyor belt

5, the rack

6, the wing housing

7, drive shaft

8. Optical Infrared emitters

9, the fixed foot

10, a control panel

Installation

1) The construction of precision instrument, should not work under

high temperature and humidity.

2) attention to the surrounding environment, should not have moving

ferromagnetic objects, such as electric fans, sewing machines.

Notwithstanding the existence of the unit circuit interference, or

should be avoided.

3) The machine should work properly fixed, shaking or vibration of

the instrument may have resulted in false alarms instrument.

4) can not carry on the work of personnel to operate the machine

contains ferromagnetic materials, such as a lot of keys, cell

phones, BB machine, steel ruler, caliper, such as a screwdriver.

maintenance

1) with horizontal gear speed reducer, normally lubricated with

grease, work should note the reduced temperature, noise. If you

want to stop in time into unusual sound, check the reason.

2) reducer can be used in various occasions indoor and outdoor,

ambient temperature is 0 ℃ -40 ℃.

3) reducer lubricated with grease, grease has to fill up the timing

within the factory. Since the newly installed gear in operation

will produce fat loss, so in the first two months should use the

grease, after use should be regularly replenish oil to ensure the

normal operation of the deceleration function and prolong life.

4) After six months of work refuel once

The picture of metal detector:

Hai Da Labtester

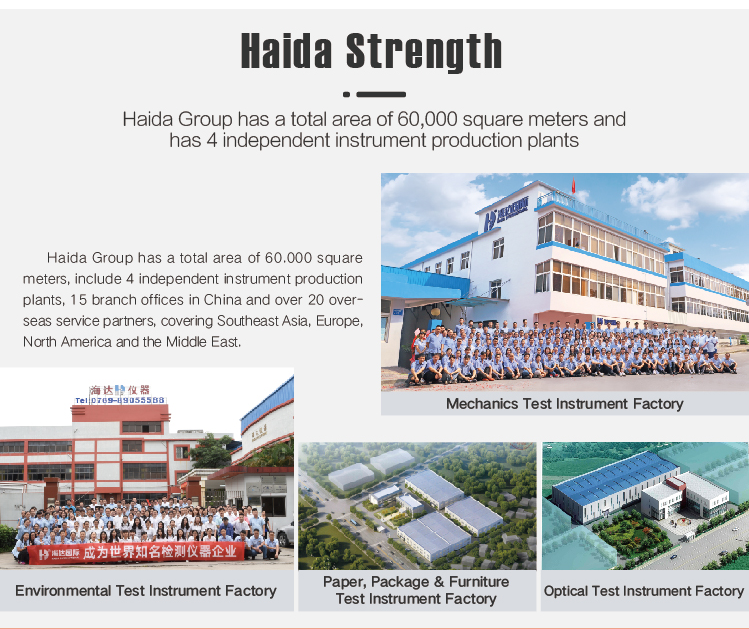

Haida International Equipment Co., Ltd Company Profile

Haida established in 2004 in Dongguan City, where is the “silicon valley” of world manufacturing industry. It is a certified national high-tech enterprise engaged in design, research and development, production, sales, calibration and after-sale service of test equipment, such as paper&packaging test equipment, Furniture test equipment, material mechanics test equipment, optical measurement equipment, environmental reliability testing equipment etc. With the persistent efforts of all staff, Haida owned 4 factories with total 60,000 square meters, 15 branch offices covers South China, North China, East China, Central China and Northwest China, as well over 20 overseas after-sales service sites covers Southeast Asia, Europe, North America and the Middle East with over 28,000 customers.

Haida main business scope includes equipment production, non-standard equipment customization, software development, measurement and maintenance consulting services. The company has passed ISO9000 certification and multiple certifications by internationally renowned testing organizations such as BV, SGS, TUV, and its products comply with GB, ISO, ASTM, EN, JIS, TAPPI, ISTA, DIN, BS and other domestic and foreign standards. Meanwhile, invested a large amount of research and development funds to adhere to the product concept of R & D , sales and products reserve to walk at the forefront of the industry. Moreover Haida participated in composing of furniture test standards and commonly drew up CY/T229-2020 industry standards with the National quality inspection, jointly developed industry test equipment with the National Paper Products Center and Dongguan Quality Testing Furniture Laboratory, co-built the reliability laboratory with many well-known enterprises, and Jointly built the dangerous articles packaging laboratory with Guangdong Huangpu Customs Technology Center.

Haida adheres to the vision of "To be the World Class Testing Equipment enterprise" and attaches importance to platform construction and talent reserves. Having 630 employee which contain 150 technicians and more than 300 bachelors, 5 Masters, and 3 PhDs. Haida have won 2 national invention patents and over 100 utility model patents, At the same time, established 5 industry-university-research cooperation bases with universities and research institutes and invited more than 20 doctoral supervisors as consultants.

Looking forward to the future, Haida will fulfill the mission of "Deliver the best testing equipment to our customers" and adhere to the core values of "Creative, Efficiency, Inheritance, Passion and Persistence". Taking a green, low-carbon, and environmentally friendly sustainable development path, Haida will continuously optimize the product structure to realize the transformation and upgrade of the enterprise itself. It is the eternal pursuit of Haida people to build Haida into a comprehensive provider of testing equipment with advanced technology, excellent quality, high-quality service, and win-win cooperation!

Haida Headquarter

Haida Facyory

Haida Team