Conveying Type Industrial Metal Detectors Ndc A Conveyor For Garment / Textile

Conveying Type Industrial Metal Detectors Ndc A Conveyor For

Garment / Textile

Specifications:

Conveying type Needle Detector

Detection size 650W*100Hmm

Fe0.8mm

detect ferrous in cloth&garment

factory,20years experi

conveyor type needle detector NDC-A/100mm

PURPOSE:

Conveying Type Industrial Metal Detectors Ndc A Conveyor For

Garment / Textile widely used in the detection cartoon toys (plush toys, soft toys),

clothing, knitwear, bedding, food (aluminum packaging), leather,

textile and other industries, for the detection of loss of raw

materials or products of ferromagnetic materials (such as iron

needle iron nails) pieces

FEATURES:

1. Cycled,9 pairs of scnsor,excellentanti-disturbance performance.

2. Based on LED bar displayed control panel.

3. Hi accuracy detection locating technology,LED indication.

4. Lovel setup indication and real-time scnsitivity display.

5. Optional conveying mode after alarm.

6. Optional automatical restart.

7. Reliability mechanical frame design,Hi stable during detection.

8. Designed for universal AC power supply,switch power supply

working principle:

When a ferromagnetic object enters the detection channel, generate

the probe up and down through a strong magnetic field sensor signal

and sends the signal to the signal receiving and processing blocks,

and then scanned with a photoelectric sensor, high voltage blocks,

sensitivity control manifold, manifold and signal reception signal

output manifold and actuators to complete the testing.

Spectifications:

Model | W801 | |||||

Window Height | 100mm | 120mm | 150mm | 200mm | 250mm | |

Window Width | 440mm | 440mm | 440mm | 440mm | 440mm | |

Sensitivity | Fe Diameter>= | 0.6mm | 0.8mm | 1.0mm | 1.2mm | 1.5mm |

SUS Diameter>= | 1.5mm | 1.8mm | 2.0mm | 2.5mm | 3.0mm | |

Power | 220V,50HZ,120W | |||||

Technology Parameters:

Model | Industrial Broken Needle Detector Machine |

Detecting Sensitivity | diameter 0.8 mm to 2.5mm iron ball |

Sensitivity adjust | 1-10 level |

Detecting Width | 60cm |

Detecting Height | 10-30cm |

Alarm method | Buzzer,Lamp |

Conveying speed | 24m/min(50Hz),32m/min(60Hz) |

Power | AC220V |

Rated Output | 60W |

Body size | 185cm(L)*105cm(W)*95cm(H) |

Composition structure:

1, the detection sensor (probe): Detection of induction by the upper and the lower detector sensors

(position below the belt) composition

2, the circuit control system: signal amplifying circuit and signal circuit alarm system, power

supply protection circuit has three major components

3, Motor: single-phase capacitor gear reduction motor rotation

4. The conveyor belt: the role of the conveyor is to be detected by detecting articles

carrying the sensor for detecting the ladder tool, it uses a

special anti-static nylon mesh woven into the warp and weft,

adhesive special rubber surface, absolute guarantee no alarm

conveyor belt without a little iron and metal components, in order

to ensure the sensor when tested

5, the rack: rack made of steel plates, reaching Needle whole bridge effect is

the primary framework Needle multifunctional state structure,

making it more stable performance, the appearance of electrostatic

spraying, both beautiful and can be extended life.

6, the wing skin: both play a decorative appearance, the early use of aluminum

production, in terms of relative iron play a role in shielding the

signal, because the aluminum shell handmade, suitable for small

production of non-standard or custom manufacturers machines,

strength of the manufacturers have to use their own mold

engineering hard plastic shell.

7, drive shaft: stainless steel tube combined with four plane propeller shaft

bearings for rolling structure, making it more transmission

concentricity ensure smooth transmission lubrication, low noise,

low heat, long life.

8. Optical Infrared emitter: when will launch a bunch of invisible infrared working condition,

when it is played by the analyte infrared intercept and transmit

signals to the recorder, eventually qualified items were counted.

9, the control panel: used to control the machine operation and sensitivity testing,

display counting functions

Hai Da Labtester

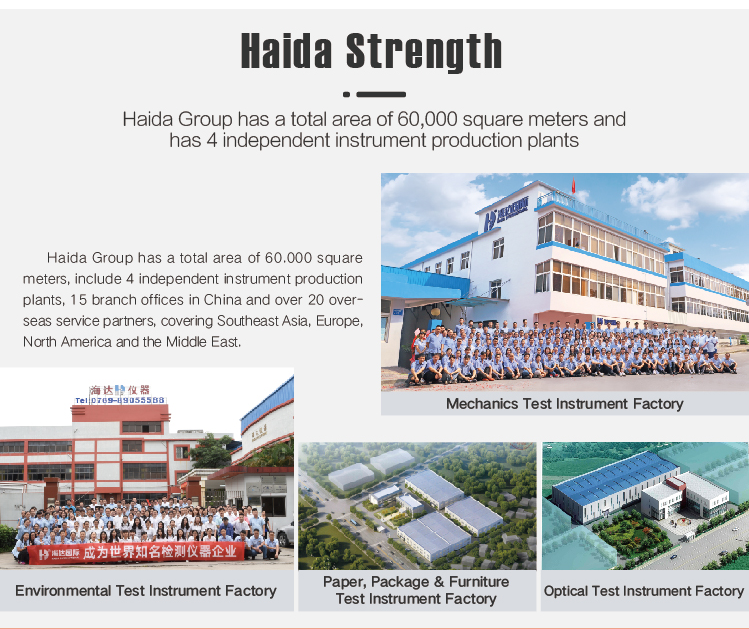

Haida International Equipment Co., Ltd Company Profile

Haida established in 2004 in Dongguan City, where is the “silicon valley” of world manufacturing industry. It is a certified national high-tech enterprise engaged in design, research and development, production, sales, calibration and after-sale service of test equipment, such as paper&packaging test equipment, Furniture test equipment, material mechanics test equipment, optical measurement equipment, environmental reliability testing equipment etc. With the persistent efforts of all staff, Haida owned 4 factories with total 60,000 square meters, 15 branch offices covers South China, North China, East China, Central China and Northwest China, as well over 20 overseas after-sales service sites covers Southeast Asia, Europe, North America and the Middle East with over 28,000 customers.

Haida main business scope includes equipment production, non-standard equipment customization, software development, measurement and maintenance consulting services. The company has passed ISO9000 certification and multiple certifications by internationally renowned testing organizations such as BV, SGS, TUV, and its products comply with GB, ISO, ASTM, EN, JIS, TAPPI, ISTA, DIN, BS and other domestic and foreign standards. Meanwhile, invested a large amount of research and development funds to adhere to the product concept of R & D , sales and products reserve to walk at the forefront of the industry. Moreover Haida participated in composing of furniture test standards and commonly drew up CY/T229-2020 industry standards with the National quality inspection, jointly developed industry test equipment with the National Paper Products Center and Dongguan Quality Testing Furniture Laboratory, co-built the reliability laboratory with many well-known enterprises, and Jointly built the dangerous articles packaging laboratory with Guangdong Huangpu Customs Technology Center.

Haida adheres to the vision of "To be the World Class Testing Equipment enterprise" and attaches importance to platform construction and talent reserves. Having 630 employee which contain 150 technicians and more than 300 bachelors, 5 Masters, and 3 PhDs. Haida have won 2 national invention patents and over 100 utility model patents, At the same time, established 5 industry-university-research cooperation bases with universities and research institutes and invited more than 20 doctoral supervisors as consultants.

Looking forward to the future, Haida will fulfill the mission of "Deliver the best testing equipment to our customers" and adhere to the core values of "Creative, Efficiency, Inheritance, Passion and Persistence". Taking a green, low-carbon, and environmentally friendly sustainable development path, Haida will continuously optimize the product structure to realize the transformation and upgrade of the enterprise itself. It is the eternal pursuit of Haida people to build Haida into a comprehensive provider of testing equipment with advanced technology, excellent quality, high-quality service, and win-win cooperation!

Haida Headquarter

Haida Facyory

Haida Team