Heavy Duty Cutting to Length Custom Roll Forming Machine PLC Control System

Heavy Duty Cutting to Length Roll Forming Machine PLC Control

System

Process flows:

slitting----- separate unit and damping institution-----recoiler

Consist part:

| Name | Qty. |

| Hydraulic decoiler | 1set |

| Slitting | 1set |

| Separate unit and damping institution | 1set |

| recoiler | 1set |

Machine capacity:

Thickness of coiled plate: 0.6-1.5mm

Width of coiled of plate: 1500mm

Precision of slitting: width tolerance about 0.5mm

Length tolerance about 2mm

Machine detail:

1. Slitting

1.1Function: orientation and feeding arrangements around the brush, to achieve positioning strip points and cut the time to stop beating strip to improve the accuracy of sub-shear.

1.2 Power section: dynamic seat, motor, tooth distribution box, universal couplings, clutches and so on.

Main machine parts: fixed arch, movable arch, movable arch mobile device, pressing the knife shaft synchronous lifting mechanism, the trimming device, up and down knife shaft, blade, spacers, frequency conversion motor (11KW), supplied with imported guide and guard, on the device and wipe the brush thin material damping mechanism, welded base and so on. Supplying six blades and spacers, rubber ring set, sub-shear specifications provided by the user.

(1) Number of blades: 7blades

(2) Main power: 11kw

(3) Speed: about 10m/min

(4) Diameter of axis: 150mm

(5) Material of slitting blade: CR12

(5) Hardness of blades: HRC55-60℃

(6) The blade size: 120mm*15mm

(7) Voltage: 380V/3PH/50HZ(or depends on customer’s requirement)

(8) Control system: PLC

2. Separate unit and damping institution

2.1 Function: Separating the steel sheet which after slitting, to adapt the material recoil. When cutting thin material to build the back pull, so that later recoiled strip neat.

2.2 Slitting shaft, mechanical manual pressure device, damping felt

3. Recoiler

3.1 Function: main machine cooperate with first slitting and second separate to recoil the finished product which after slitting, coil win ding tension and winding speed both can be adjustable.

3.2 Base, shaft, rack, wedge-type sizing mechanism, hydraulic shrink oil cylinder, hydraulic station (2.2KW) inverter motor (30KW) and gear box, shaft material pressure points.

(1) Inner Diameter: Φ508 – Φ610 mm

(2) Out Diameter: 1500 mm

(3) Max. Loading Capacity: 10T

(3) Power: 30kw

(4) Type: hydraulic

After-sales service

Technical Support

Fully providing technology supports both within and after the

warranty period. Feed back to our customers at the first time.

Spare Parts

Promptly providing spare parts and wearing parts.

Upgrade

Improve technology and upgrade of equipments.

sandwich panel production line good price

RFQ

Q: How can I contact you?

A: Please look at my contact card. You can talk to me anytime. Or send me enquiry email, I will reply you in 24 hours and offer the optimum solution to you

Q: What is the status of After-sale Services for customers and machineries?

A: Engineers available to service machinery overseas. But the customers/buyer should pay for installation and commissioning fee 80$/day to our point account. We will provide the technical support for the whole life of the equipment and free training.

Q: How to visit our company?

A: 1. Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

2. Fly to Shanghai Airport: By high speed train From Shanghai

Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3. Fly to Guangzhou aiport: By air From Guangzhou to Beijing

airtpot; By high speed train From Beijing Nan to Cangzhou Xi (1

hour),then we can pick up you.

Q: How many years since you have been in this field?

A: Our company has been producing roll forming machines for almost 20years.We have rich experience for manufacturing and designing the machine.

Machine Photo

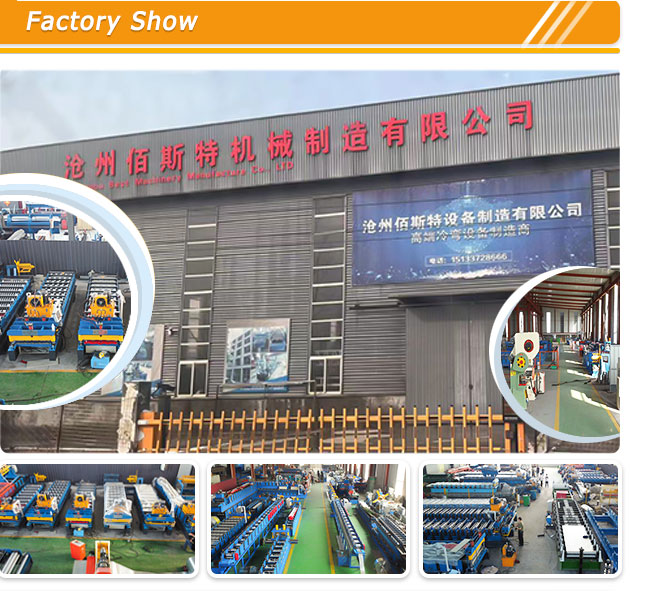

Cangzhou Best Machinery Co., Ltd

Cangzhou Best Machinery Co., Ltd set up in 2015, with great power in production and techniques, we are a leading manufacturer of roll forming machines in North of China.We have two workshops more than 4000 square meters, and have own processing machines and design engineer, so that can control machine production time and quality;Our factory is near Beijing or Tianjing, and in Cangzhou there is railway station, so it is convinent transport.Welcome to visit our factory anytime.

Our main products are CUSTOMIZED ROLL FORMING MACHINES, because

clients will use roll forming machines instead of bending machine

or pressing machines to save labor, and improve production, our

regular products are roof sheet roll forming machine, roof tile

roll forming machine, CZ roll forming machine, floor decking roll

forming machine, highway guardrail roll forming machine, cable tray

roll forming machine, stud and track roll forming machine, door

roll forming machine, slitting and cut to length, sandwich panel

machine and so on.

We have advanced production equipment and our engineering personnel

and technicians have extensive experience in designing, developing,

and manufacturing machineries. They pay close attention to and keep

up with the developing trend of technologies and use new

technologies in manufacturing machinery, to keep them competitive.

Our products feature high efficiency, high flexibility and low

cost.

"Customers are the first, success comes from development" is our

principle. We bear this in mind during the whole process from

design and development of product to after-sales services. We will

design and manufacture machinery strictly in accordance with your

requirements.

With good after-sales service network, we can provide support

covering the whole process of purchasing, which help you get

perfect machinery. We'll solve all the problems you have while

using the machines and we'll provide considerate services.

Our machines have been sold to North America, like US, Canada, South America, Nicaragua, Peru, Brazil, Bolivia, Uruaguy, Argentina, Europe, like Greece, Middle east, like Saudi Arab, Dubai, Iran, Iraq, Africa, Egypt, Ghana, Nigeria, Ethiopia, Malawi, Kenya, Tanzania, Zambia, Zimbabwe, South Africa, Australia, New Calidonia, Asia, India, Thailand, Philippines, Indonesia, Papua New Guinea,

Bangladesh, Pakistan, Turkmenistan, Malaysia, Vietnam, Mongolia, helping us enter the

international market.

Excellent service and high technology assist you to create a bright

future.

To make sure machine quality, we applied CE certificate and SGS

certificate and so on.

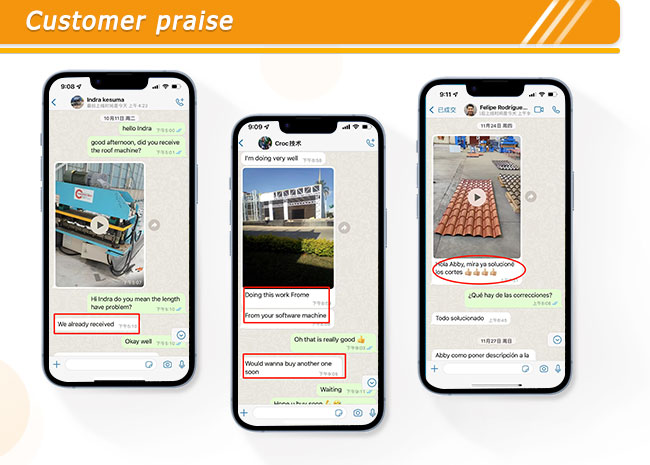

Our roll froming machine exported all over the world and win good repution,clients give good feedback,we have been exported to more than 120 countries and regions in the world, including: Germany, Japan, Italy, Russia, Japan, South Korea, Turkey, Brazil , India, the United Arab Emirates, Saudi Arabia and other countries, the products are subject to a great welcome and praise. INDIA, AFRICA, SOUTH AMERICA.

WE WILL YOUR BEST SUPPLIER IN CHINA,WELCOME TO CONTACT US.