100-600mm Adjustable Bridge Cable Tray Machine / Production Line Low Noise

100-600mm Adjustable Bridge Cable Tray Roll Forming Machine Production Line

1. What is the Application of cable tray machine?

Galvanized Steel cable tray machine is a kind of equipment for making cable tray by various material. In the electrical wiring of buildings, a cable tray system is used to support insulated electric cables used for power distribution and communication. Cable trays are used as an alternative to open wiring or electrical conduit systems, and are commonly used for cable management in commercial and industrial construction. They are especially useful in situations where changes to a wiring system are anticipated, since new cables can be installed by laying them in the tray, instead of pulling them through a pipe. For Canzgou Best cable tray roll forming machine is a kind of machine for making cable tray by roll forming principle.

2. Parameters:

de-coiler

Parameter: width of material: 225-1020mm thickness: 1-2mm;Inner diameter of coil: 508mm;inner expansion range: 480-520 mm;

The maximal of Diameter: 1500mm; The Maximal of loading: ≤5T

Motor power: 5.5kw frequency change control

Press material type: pneumatic press material

Feeding speed: 0-15m/min, adjustable

Leveling machine of fully automatic cable tray machine

A: working roller: nine rollers type leveling machine

B: Feature of structure: after the quenching and tempering, chrome-plating processing, the rigidity, surface roughness of the roller etc. are all enhance greatly; It is composed by the clamping roller and the leveling roller, the clamping roller may the independent control, the leveler has one pair of horizontal guide roller and two pairs of vertical guider roller and easy to adjust by hand wheel. Between the leveler and the feeding device, there is optical sensor, sends out the feedback signal to the control system, the control system sends out the instruction to the frequency conversion motor to change speed, Achieves the uninterrupted level goal.servo feeding machine

A: function: material feedingb. Feature: Uses the servo motor-driven .Multistage type feeding: May input 10 group of different feeding lengths. The liquid crystal touching screen demonstrated is advantageous for the change, establishes various technical parameters. The auto-induction start system and the punch press linkage (control punch press start).

Punching press of

Model of punching press: JF21-120BRoll forming part

Forming station: 14setsForming variety: bridge frame

The diameter of the roller axis: 85mm

Hydraulic cutting

Cutting type: hydraulic cuttingBlade type: close type die cavity cutter

Hydraulic power:5.5kw

Material of blade: Cr12, quench treatment, hardness HRC56-58

Quantity: 9 (depend on customer request)

Run-out table

Structure: roller type with no power

Electric control system

A: Full line is controlled by PLC control system,touch screen

operation to achieve the human and PLC interactive. The operator

can monitor the setting program (programmable control) and modify

the parameter to control the line. Also can check the running

status, parameter and error indication etc..

B: Operation type: manual /auto two type switch. In manual

position: can run the each part of the machine. In auto position:

can run the full line. The emergency was stopped ensure the safe of

the equipment and operator.

3. Specifications:

Standard Specifications * Non standard specification are available upon customer's requirements. | ||||

| No. | Width (mm) | Height (mm) | Thickness (mm) | Standard Length (mm) |

| 1 | 50 | 13, 15, 20, 25,50, 75, 100 | 1.5 - 3.0 | 3000 |

| 2 | 75 | 13, 15, 20, 25,50, 75, 100 | 1.5 - 3.0 | |

| 3 | 100 | 13, 15, 20, 25,50, 75, 100 | 1.5 - 3.0 | |

| 4 | 150 | 13, 15, 20, 25,50, 75, 100 | 1.5 - 3.0 | |

| 5 | 200 | 13, 15, 20, 25,50, 75, 100 | 1.5 - 3.0 | |

| 6 | 225 | 13, 15, 20, 25,50, 75, 100 | 1.5 - 3.0 | |

| 7 | 300 | 13, 15, 20, 25,50, 75, 100 | 1.5 - 3.0 | |

| 8 | 400 | 13, 15, 20, 25,50, 75, 100 | 1.5 - 3.0 | |

| 9 | 450 | 13, 15, 20, 25,50, 75, 100 | 1.5 - 3.0 | |

| 10 | 500 | 13, 15, 20, 25,50, 75, 100,150 | 1.5 - 3.0 | |

| 11 | 600 | 13, 15, 20, 25,50, 75, 100,150,200 | 1.5 - 3.0 | |

| 12 | 700 | 13, 15, 20, 25,50, 75, 100,150,200 | 1.5 - 3.0 | |

| 13 | 750 | 13, 15, 20, 25,50, 75, 100,150,200 | 1.5 - 3.0 | |

| 14 | 800 | 13, 15, 20, 25,50, 75, 100,150,200 | 1.5 - 3.0 | |

| 15 | 900 | 13, 15, 20, 25,50, 75, 100,150,200 | 1.5 - 3.0 | |

4. Photos:

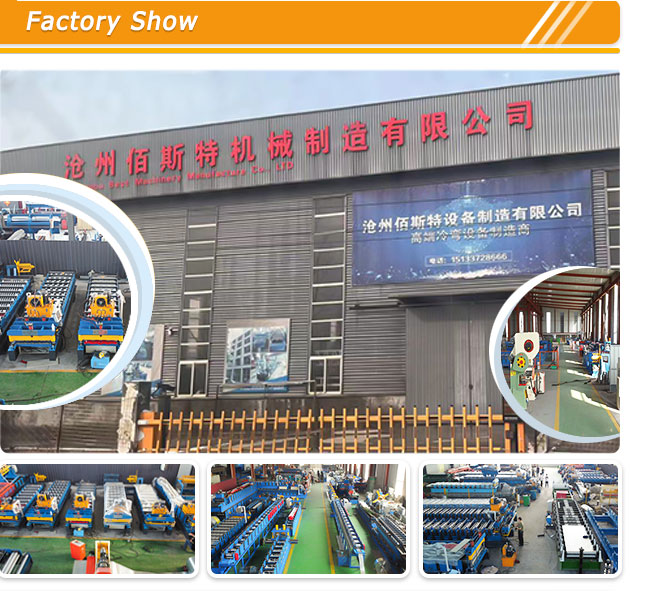

Cangzhou Best Machinery Co., Ltd

Cangzhou Best Machinery Co., Ltd set up in 2015, with great power in production and techniques, we are a leading manufacturer of roll forming machines in North of China.We have two workshops more than 4000 square meters, and have own processing machines and design engineer, so that can control machine production time and quality;Our factory is near Beijing or Tianjing, and in Cangzhou there is railway station, so it is convinent transport.Welcome to visit our factory anytime.

Our main products are CUSTOMIZED ROLL FORMING MACHINES, because

clients will use roll forming machines instead of bending machine

or pressing machines to save labor, and improve production, our

regular products are roof sheet roll forming machine, roof tile

roll forming machine, CZ roll forming machine, floor decking roll

forming machine, highway guardrail roll forming machine, cable tray

roll forming machine, stud and track roll forming machine, door

roll forming machine, slitting and cut to length, sandwich panel

machine and so on.

We have advanced production equipment and our engineering personnel

and technicians have extensive experience in designing, developing,

and manufacturing machineries. They pay close attention to and keep

up with the developing trend of technologies and use new

technologies in manufacturing machinery, to keep them competitive.

Our products feature high efficiency, high flexibility and low

cost.

"Customers are the first, success comes from development" is our

principle. We bear this in mind during the whole process from

design and development of product to after-sales services. We will

design and manufacture machinery strictly in accordance with your

requirements.

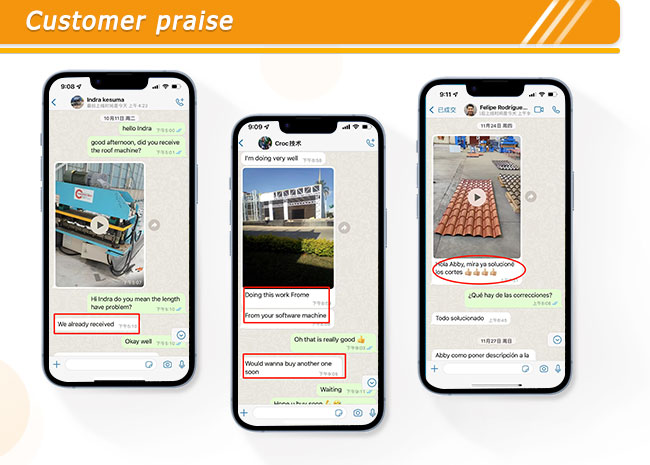

With good after-sales service network, we can provide support

covering the whole process of purchasing, which help you get

perfect machinery. We'll solve all the problems you have while

using the machines and we'll provide considerate services.

Our machines have been sold to North America, like US, Canada, South America, Nicaragua, Peru, Brazil, Bolivia, Uruaguy, Argentina, Europe, like Greece, Middle east, like Saudi Arab, Dubai, Iran, Iraq, Africa, Egypt, Ghana, Nigeria, Ethiopia, Malawi, Kenya, Tanzania, Zambia, Zimbabwe, South Africa, Australia, New Calidonia, Asia, India, Thailand, Philippines, Indonesia, Papua New Guinea,

Bangladesh, Pakistan, Turkmenistan, Malaysia, Vietnam, Mongolia, helping us enter the

international market.

Excellent service and high technology assist you to create a bright

future.

To make sure machine quality, we applied CE certificate and SGS

certificate and so on.

Our roll froming machine exported all over the world and win good repution,clients give good feedback,we have been exported to more than 120 countries and regions in the world, including: Germany, Japan, Italy, Russia, Japan, South Korea, Turkey, Brazil , India, the United Arab Emirates, Saudi Arabia and other countries, the products are subject to a great welcome and praise. INDIA, AFRICA, SOUTH AMERICA.

WE WILL YOUR BEST SUPPLIER IN CHINA,WELCOME TO CONTACT US.